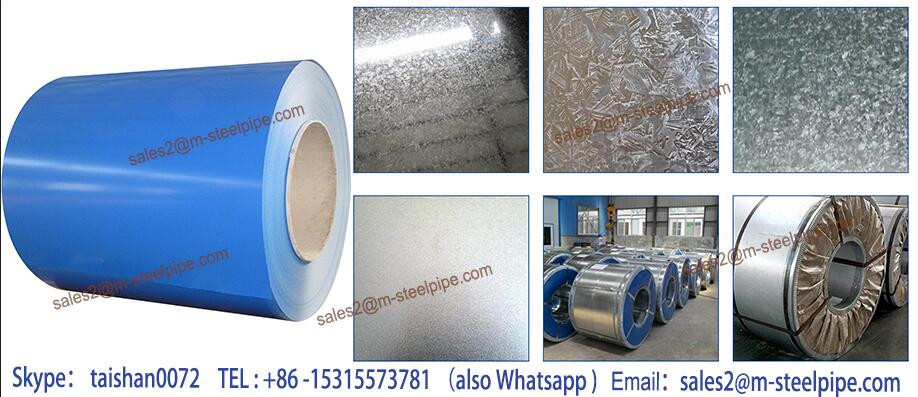

Three types of galvanized steel coils |

All of our galvanized steel coils are made of Cold Rolled Steel.Cr steel coil products with good finishing and easily formed advantage can be widely used in Automobiles,Refrigerators,Washing machines,Industrial equipments, and all kinds of building materials.

Our compnay can manufacture three types of galvanized steel coils:

• Hot dipped Galvanized steel coil (SGCC,SGCD,SGCE)

• Electrogalvanized steel coil (SECC,SECD,SECE)

• Hot dipped Galvalume Steel Coil (GL)

| Detailed Specification of GI Steel Coil |

Type-01:Hot dipped Galvanized Steel Coil

| Substrate | Cold Rolled Steel Coil |

| Steel Grade | DX51D+Z~DX56D+Z,DC51D,Q195,Q235,Q235A,ST02Z,CS-B,etc |

| Standard | JIS G3302-2007, GB/T2518-2008,ST02Z, DIN EN 10327, ASTM A653 |

| Thickness | 0.14mm~1.0mm |

| Width | 600mm~1250mm |

| Zinc Coating | Z40~Z60/ Z80~Z100/ Z120~Z150/ Z275 |

| Spangle | regular spangle, minimum spangle |

| Edge | mill edge,cut edge |

| Surface Treatment | Chromated,Oiled,Anti-finger print (N) |

Type-02:Electrogalvanized Steel coil

| Substrate | Cold Rolled Steel Coil |

| Steel Grade | DC01+ZE, SECCN5, CR4, ZStE180BH+ZE,etc |

| Standard | JIS G3302-2007, GB/T2518-2008,DIN EN 10327, ASTM A653 |

| Thickness | 0.14mm~1.0mm |

| Width | 600mm~1250mm |

| Zinc Coating | E8,E16,E24,E32 |

| Edge | mill edge,cut edge |

| Surface Treatment | Oiled,Phosphate (P),Anti-finger print (N) |

Type-03:Hot dipped Galvalume Steel Coil

| Substrate | Cold Rolled Steel Coil |

| Thickness | 0.14mm~2.0mm |

| Width | 600mm~1250mm |

| Spangle | Regular, Zero |

| Treatment | Skin-passed,Chromated,AFP,Oiled |

| Quality | CQ,DQ,HSLA |

| Detailed Photos of GI Steel Coil |

| Factory Processes |

Processes of Cold Rolled Coil

Cold rolled production lineis runing in the form of 4 convertible roller in single framework,The material:Lower Carbon steel(CQ,DQ,DDQ),Lower Carbon high tensile steel(Q195,Q235,Q345),SHLA steel,deep drawing steel and IF steel.Cover thickness:0.23~1.50mm,width:600~1250mm.

4 convertible Roller machine

| Name | Thicnkess (mm) | Width (mm) | Coils ID (mm) | Side Condition | Surface Condition |

| Cold Rolled Coils (CRC) | 0.14~1.0 | 600~1250 | 508/610 | rolling side | bright |

Processes of Hot Dipped Galvanized Steel Coil

Hot Dipped Galvanized Steelis widely used in auto, household electrical appliance, IT, adnvaced building materials industries, etc.The process of producing hot dipped galvanized steel is: Cold Rolled Full Hard - Payoff Reels - Degreasing - Annealing - Zinc Coating - Tension Leveling - Straightedge Forming - Chromeate or Oil.

| Characteristics of the Continuous Galvanizing Line |

| • Adopt roll-painting-chromated technology, ensure the Cr Free and envirinmentally-friendly process. |

| • High-level automatic control system ensures the efficiency and product quality. |

| • Product is able to be well shaped after tension leveling and straight forming. |

| • GI production line equipped with chromated, oiled and anti-finger print facilities can reach customers' requirements. |

| • Zinc coating control system and technology imported from France guarantees the uniformity of zinc coating. |

| • The USS method applied in galvanizing thchnology ensures the high quality of adhesion and surface treatment. |

Processes of Electro Galvanized Steel Coil

| Pakcage and Shipping |

| Certificate |

| Contact us |

Tel: 86-22-27989909-802

Fax: 86-22-27989919-817

Galvanized steel coil is used special steel coil as raw material and surfaces (covered with) is painted a layer of organic polymer (or polymer print film),which has advantages of metal material and the organic polymer,DX51D Galvanized steel coils and sheet, 0.3mm thick cold rolled steel steel strip coils zinc coating 30g-275g not only good adhesive of Organic polymer,formability,corrosion resistance,decorative,but also high strength and easy processing,Galvanized steel coil can be easily punching,bending,deep drawing,welding,etc. So DX51D Galvanized steel coils and sheet, 0.3mm thick cold rolled steel steel strip coils zinc coating 30g-275g has perfact practicality, decorative,workability,durability.Currently,the PCM is produced by print film roller coating process and roller painting.

JHBJHV

DX51D Galvanized steel coils and sheet, 0.3mm thick cold rolled steel steel strip coils zinc coating 30g-275g According to the different production process ,household appliances of color coating steel paltecan be divided into PCM and VCM with printing film.PCM is used for Galvanized steel coil refrigerators,washing machines,freezers and other appliances door,electric appliances lateral plate,microwave ovens,video disc,LCD TV's backplane;VCM is mainly used for refrigerators,washing machine and other appliances.