Product Description

201 304 4x8 Mirror finish gold rose colored stainless steel plates for elevator construction

Material: 201/304 stainless steel

Size: 4 x 8ft or 4x10 ft or customized

Color: PVD color or water cooper

Surface treatment: Printing+etched and PVD color

Application: Be extensively applied to architectural decoration, such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade, etc.For furniture, kitchenware, food industry, electronic industry, medical equipment, etc.

| Product Information | |

| Type |

Decorative Stainless steel sheet |

| Thickness |

0.3 mm - 3.0 mm |

| Size |

1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max. width 1500mm |

| Grade |

201,304, 304L,316,316L,430 etc. |

| Surface Finishes |

No.4, Hairline, Mirror, Etched, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination etc. |

| Standard |

ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

| Available Color |

Gold, Rose gold, Champagne gold, Copper, Bronze, Black, Blue, Purple, Green etc. |

| Origin |

POSCO,JISCO,TISCO,LISCO,BAOSTEEL etc. |

| Advantages |

strong corrosion resistance and decorative effect, durable and beautiful in good taste.Showing the splendor of your quality, wearresistant as well , |

| Packing way |

PVC+ waterproof paper + strong sea-worthy wooden package or customized |

| Application |

Be extensively applied to architectural decoration, such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade, etc.For furniture, kitchenware, food industry, electronic industry, medical equipment, etc. |

| Chemical Composition | ||||

| Grade | STS304 | STS 316 | STS430 | STS201 |

| Elong(10%) | Above 40 | 30MIN | Above 22 | 50-60 |

| Hardness | ≤200HV | ≤200HV | Below 200 | HRB100,HV 230 |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60% | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12% | ≤0.15 |

Related Products

Related Products

Production Process

Production Process

PVD Color

PVD is the abbreviation of Physical Vapor Deposition. It is a process carried out in high 201 304 4x8 Mirror finish gold rose colored stainless steel plates for elevator construction at temperatures between 150 and 500 .PVD stands for Physical Vapor Deposition, which refers to under the condition of 201 304 4x8 Mirror finish gold rose colored stainless steel plates for elevator construction, use Physical method to make material preparation technology of thin film deposited on the plated , A range of colors are available, including gold, black, bronze, blue and so on.

Brushed Finish

Metal is metal with a unidirectional satin finish. It is produced by polishing the metal with a 120–180 grit belt or wheel then softening with an 80–120 grit greaseless compound or a medium non-woven abrasive belt or pad. Brushing gives metal a distinctive look, as it retains some but not all of its metallic luster and is given a pattern of very fine lines parallel to the brushing direction.

Etched Finish

The coloring of stainless steel can be achieved by chemical surface treatment which actually modifies the surface oxide film on the metal. The colored finish is attractive but susceptible to finger-marks, which results in a color change and is not hard-wearing, and this should be considered when deciding on the use. The process uses acidic solution which, due to the variances in composition of the stainless and the process variables, can be guaranteed to be the same every time

Sandblasted Finish

A sandblasting setup usually consists of three different parts: the abrasive itself, an air compressor, and a blaster nozzle. For etching and small object cleaning, a workstation to hold the piece of glass is also needed, as is some sort of collector to gather up excess dust.

Mirror Finish

Mirror finish is created by mechanically treating the surface with a series of progressively finer abrasives. Alternatively a special rolling procedure is used which can simulate the appearance of mechanical abrasion. For this stage, it is essential to remove deep scratches as any surface defects will be very noticeable on the finished product. The final process involves buffing the surface for 5-10 minutes to create a mirror-like, highly reflective finish.

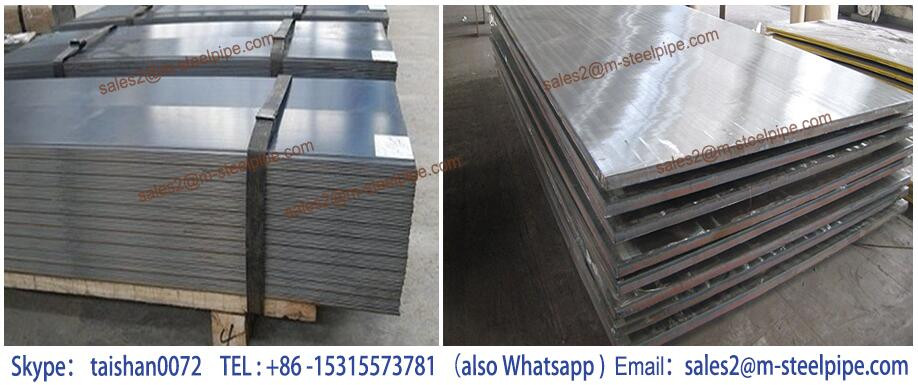

Packing & Delivery

Packing & Delivery1 Sheets covered with wooden plate for protection in transportation.

2. All sheets will be loaded in strong wooden packages.

3. Every cartons loaded with good shoring and strengthening.

4. Take container loading pictures and seal the container.

5. Transportation speed is quick. And keep customer each step informed.

FAQ

FAQQ1.How can I get some samples?

A1.Small samples are in store and can provide the samples for free. Catalog is available, most patterns we have ready samples in stock. Customized samples will take about 5-7days.

Q2.What do you do to control your quality?

A2.From the technology,our product is 100% by 3 coating and 3 baking. From the quality inspection, we have QC engineers responsible for Incoming Inspection,Processing Inspection and Finished Product Inspection.

Q3.If the order is too large , can you ensure in time delivery?

A3.Sure! Our factory with high productive force and we have the advanced technology devices which make us ensure in-time delivery.

Q4.How to protect the stainless steel sheets?

A4.Two white and black PE layers to cover the surface, each layer is 70 micro (Total 140 micro), laser PVC is also workable.( Novacel or poli-film brand )

Steel Plate has lots of good quality: surface is smooth, high plasticity, toughness and mechanical strength, resisting acid and alkali corrosion of gas, solution, and other media.201 304 4x8 Mirror finish gold rose colored stainless steel plates for elevator construction is a kind of alloy steel and not easy to rust, but not absolutely not to rust. Stainless steel plate can resist weak media such as air, Steel Plate steam and water corrosion resistance of steel, acid steel plate refers to the nedia, resisting chemical etching media such as acid, alkali, 201 304 4x8 Mirror finish gold rose colored stainless steel plates for elevator construction salt corrosion of the steel plate. Since the beginning of the 20th century, and stainless steel plate has a history of more than a century.

jhgjhbjh

Steel Plate used for architectural decoration, luxury doors, elevators decorating, metal tank shell, ship building, decorated inside the train, as well as outdoor works,201 304 4x8 Mirror finish gold rose colored stainless steel plates for elevator construction advertising nameplate, the ceiling and cabinets, aisle panels, screen,Steel Plate the tunnel project, hotels, guest houses, entertainment place,kitchen equipment,light industrial and others.